Redwater Ethylene Injection Site

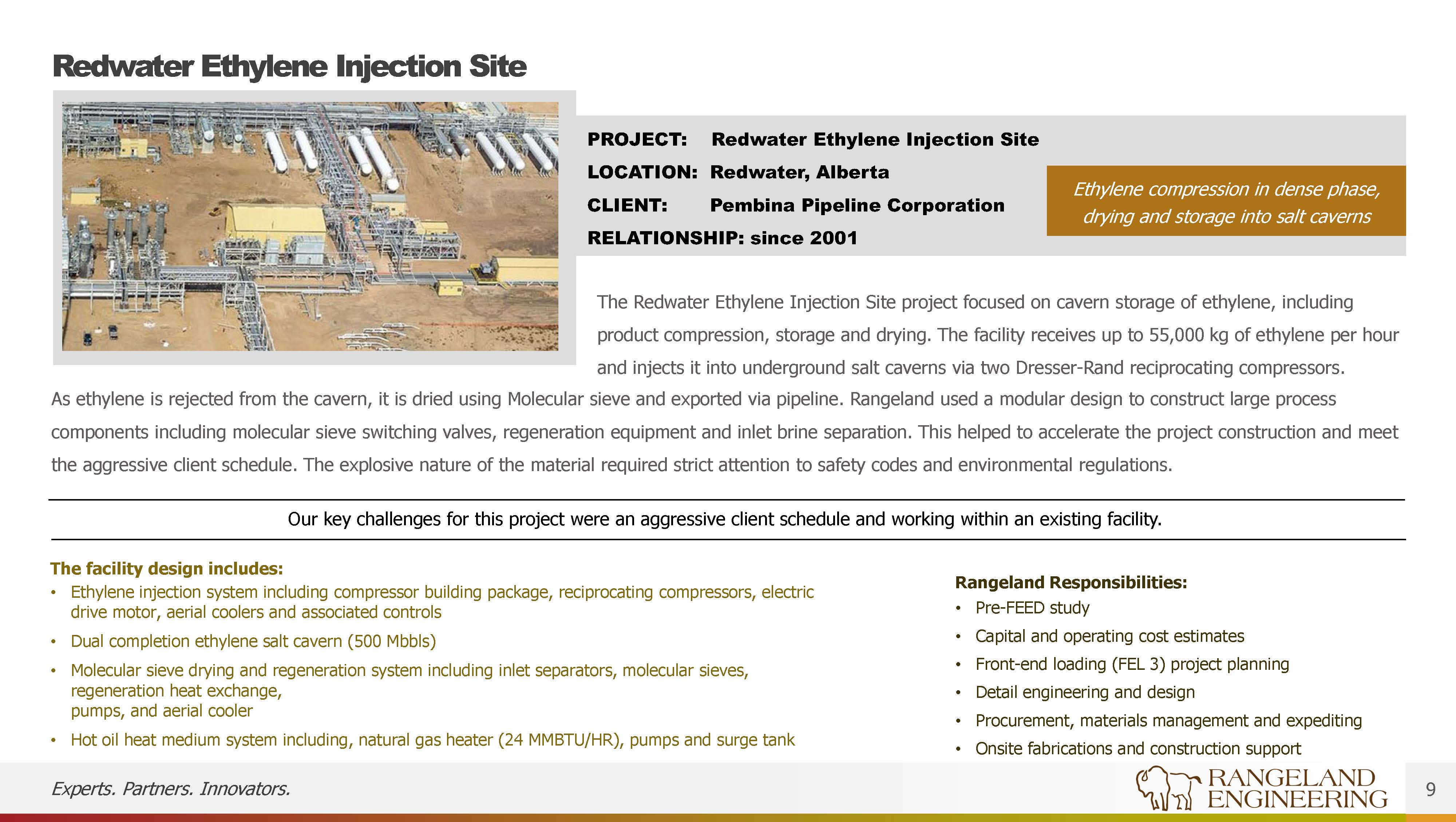

The Redwater Ethylene Injection Site project focused on cavern storage of ethylene, including product compression, storage and drying. The facility receives up to 55,000 kg of ethylene per hour and injects it into underground salt caverns via two Dresser-Rand reciprocating compressors.

The facility design includes:

•Ethylene injection system including compressor building package, reciprocating compressors, electric drive motor, aerial coolers and associated controls

•Dual completion ethylene salt cavern (500 Mbbls)

•Molecular sieve drying and regeneration system including inlet separators, molecular sieves, regeneration heat exchange, pumps, and aerial cooler

•Hot oil heat medium system including, natural gas heater (24 MMBTU/HR), pumps and surge tank

Our key challenges for this project were an aggressive client schedule and working within an existing facility.

Rangeland Responsibilities:

•

Pre-FEED study

•

Capital and operating cost estimates

•

Front-end loading (FEL 3) project planning

•

Detail engineering and design

•Procurement, materials management and expediting

•Onsite fabrications and construction support

As ethylene is rejected from the cavern, it is dried using Molecular sieve and exported via pipeline. Rangeland used a modular design to construct large process components including molecular sieve switching valves, regeneration equipment and inlet brine separation. This helped to accelerate the project construction and meet the aggressive client schedule. The explosive nature of the material required strict attention to safety codes and environmental regulations.