Product Storage

Rangeland Engineering delivers innovative and reliable product storage solutions tailored to the energy and industrial sectors. Our expertise spans tank farms, terminals, underground storage, and pressurized systems, ensuring safe and efficient handling of hydrocarbons, chemicals, and other bulk commodities.

From concept to commissioning, we optimize tank sizing, material selection, and automation to enhance performance, reduce costs, and meet regulatory requirements. Whether designing new storage facilities or upgrading existing infrastructure, Rangeland provides scalable, cost-effective solutions that align with operational needs and long-term sustainability goals.

Trust Rangeland for your product storage solutions—built for performance, safety, and longevity.

-

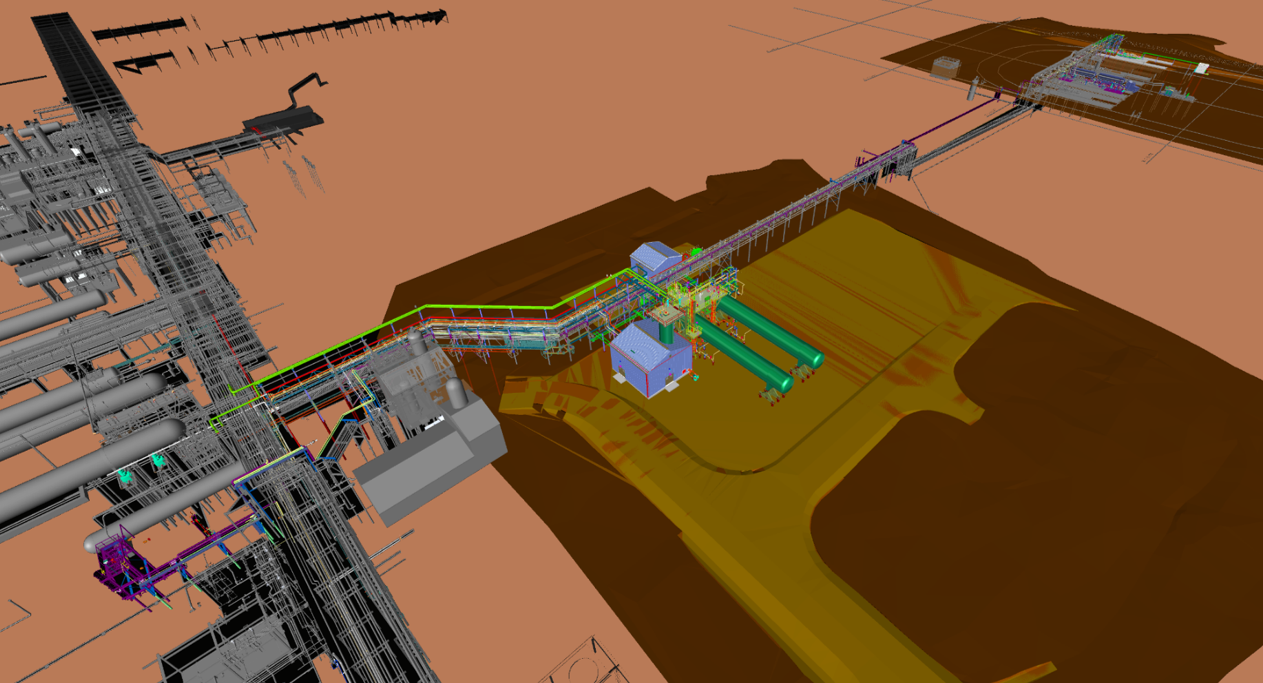

ROF Butane Loading

To access new customers for butane, expansion of the existing rail and truck loading infrastructure was required. This expansion included four new rail car and two new truck loading stations. To address sales specifications, a calcium chloride dehydration unit was required. Other accessory equipment required to support this project were two storage bullets, and three centrifugal pumps.

The facility design included:

• A calcium chloride dryer

• Moisture analyzer

• Filter

• Two butane storage bullets for feed to loading pumps

• Truck and rail loading pumps

• New MCC

• Modified site grading

• Modified pipe racks -

Ethane Storage Facility

The two salt caverns are designed to hold 500,000 barrels of

ethane each for a total storage capacity of 1,000,000 barrels.The plan includes three brine disposal wells and two storage caverns with long term capability to create additional caverns.

The facility design includes:

• Two hydrocarbon storage caverns with 500,000-barrel capacity

• Three brine disposal wells for safe discard of saturated brine during wash phase

• Three wash water pumps (800 HP each) and three brine disposal pumps (700 HP each)

• Two ethane injection pumps (1,250 HP each) and two brine transfer pumps (75 HP each)

• Dehydration/regeneration system including mole sieve dryers, heater, cooler, filter, separator, and coalescer

• Utilities/infrastructure including brine ponds, settling tanks, motor control centers, control room/office, nitrogen purge, instrumentation and controls, electricity, instrument/utility air, lighting, uninterrupted power supply, process buildings, maintenance shop, roads, drilling pads, fuel gas, and flare system -

Condensate Offloading Rail Terminal

This 16-station rail off-loading facility injects nitrogen vapour to offload condensate from rail cars into storage bullets. The condensate is then blended with crude to upgrade the quality of the product for export to pipeline.

The facility design includes:

• 16 station rail unloading

• Two API storage tanks and two bullets

• Butane and condensate blending

• Product mixers complete with controls—RVP control

• Two product pipeline pumps